Verification and Validation – Product, Process or Equipment and QMS Software

Duration : 90 Minutes

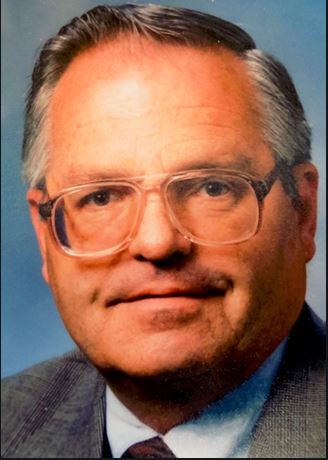

John E. Lincoln,

John E. Lincoln, is Principal of J. E. Lincoln and Associates LLC, a consulting company with over 38 years experience in U.S. FDA-regulated industries, 24 as an independent consultant. John has worked with companies from start-up to Fortune 100, world wide. He specializes in quality assuranc Read more

FDA Warning Letters and recent high-profile recalls indicate major cGMP deficiencies in big name device and pharma companies. One major failing is lack of sufficient or targeted risk-based V&V planning and execution. But a review of Internet forums shows confusion as to what is V&V planning. What really is a Master Validation Plan? Why do companies need one? What is the individual V&V plan and its high value. What are the "must have" elements from ISO 14971 and ICH Q9 for hazard analysis and product risk management? How can these be integrated? What are the differences and similarities between Product, Equipment (production and lab/test), Process, and QMS V&V. How to structure software / firmware V&V so it’s acceptable to the FDA?

Course Objectives:

What is Verification? Validation? Pharma. Medical Devices. Review the company Validation Master Plan for purpose and content. Address the FDA's newer and tougher regulatory stance on V&V. One major failing is lack of sufficient or targeted risk-based V&V planning. Starting with a Validation Master Plan, evaluating its elements against ISO 14971 and ICH Q9 for hazard analysis and product risk management, allows the development of meaningful product and process validations. Also the role of the individual V&V plan. The different validation protocols; how to employ equipment / process DQs, IQs, OQs, and PQs, or their equivalents, against a background of limited company resources. Our matrix simplifies "as-product", in-product", process and equipment, et al, software VT&V, assuring key FDA requirements are not overlooked. The QMS and 21 CFR Part 11 are also discussed. The information provided will allow the project leader to develop key milestones / tasks for a successful V&V project, that have cleared FDA and Notified Body review.

Why Should You Attend:

Both the U.S. FDA CGMPs and Guidance Documents and EU's MDD/MDR and standards require documented risk-based "master" and "individual" V&V planning and execution with clearly documented Test Reports / Protocols.

Course Outline:

Verification or Validation – what is it in a real-world environment?

• Recent regulatory expectations.

• The Master Validation Plan.

• The Individual V&V Plan.

• What Are, When / How to Use DQ, IQ, OQ, PQ, ASTM E2500 Equivalents.

• Using the Risk Management tools of ISO 14971 and ICH Q9

• Product V&V versus Process / Equipment V&V.

• Product V&V versus Process / Equipment V&V.

• Key recent compliance problems

What You Get:

• Training Materials

• Live Q&A Session with our Expert

• Participation Certificate

• Access to Signup Community (Optional)

• Reward Points

Who Will Benefit:

• Senior and Middle Management

• Validation

• Marketing

• QA/RA

• Supervisors

• R&D

• Engineering

• Software Engineering

• Operations

Please reach us at 1-888-844-8963 for any further assistance or if you wish to register